The Sustainable Standard: A New Era for Printing

Sustainability is no longer a niche concern; it’s a core business mandate for large corporations and consumer-facing brands. When a company chooses a printing partner, they are scrutinizing every material, every process, and every energy output. For Eastern Press, this shift means aligning our commitment to the planet with our clients' needs for high-volume, uncompromising quality.

The key question for today's commercial print industry is: How do we innovate for environmental responsibility without sacrificing the speed and vividness that brands demand?

Why Sustainability is the New Commercial Standard

For major brands, eco-friendly printing is vital for two reasons:

Consumer Trust and Loyalty: Modern consumers, especially millennials and Gen Z, actively seek out and pay more for products from brands that prioritize sustainability. Printing on FSC-certified paper or using vegetable-based inks allows our clients to communicate their ethical values directly through a tangible product, strengthening brand loyalty.

Corporate Mandate and Compliance: Large corporations operate under strict ESG (Environmental, Social, and Governance) goals. By partnering with a printer that can prove minimized waste and energy use, our clients can significantly reduce their own measured environmental footprint and maintain regulatory compliance.

Innovation in the Press Room: Zero Compromise

At Eastern Press, we have focused our investments on two key technological areas that deliver major environmental benefits alongside superior results:

1. Energy-Efficient UV LED Curing: Traditional printing often relies on heat-heavy drying methods. We use LED UV Curing technology, which instantly dries ink using low-energy ultraviolet light. This innovation slashes energy consumption significantly, generates less heat, and eliminates the need for Volatile Organic Compounds (VOCs) in the drying process. Crucially, because the ink cures instantly, it enables faster production speeds and immediate finishing, ensuring quick turnarounds without environmental compromise.

2. Optimizing Material Usage with Digital Workflow: We use advanced imposition software and digital workflows to maximize efficiency. This technology analyses every job file to determine the tightest arrangement (or "nesting") of print pieces onto the sheet, drastically reducing material consumption and paper waste. Furthermore, our shift towards digital press solutions for short-to-medium runs eliminates the need for printing plates, saving on aluminium, water, and chemical development associated with traditional offset setups.

Quality and Speed, Unaffected

The pursuit of sustainability should never be viewed as a quality downgrade. Modern eco-friendly materials are specifically engineered for commercial excellence:

Eco-Friendly Inks: We have successfully transitioned to Soy and Vegetable-Based Inks which are easier to de-ink during the recycling process and contain fewer harsh chemicals than petroleum-based alternatives. These inks deliver the same rich, vibrant colour saturation that high-end advertising requires.

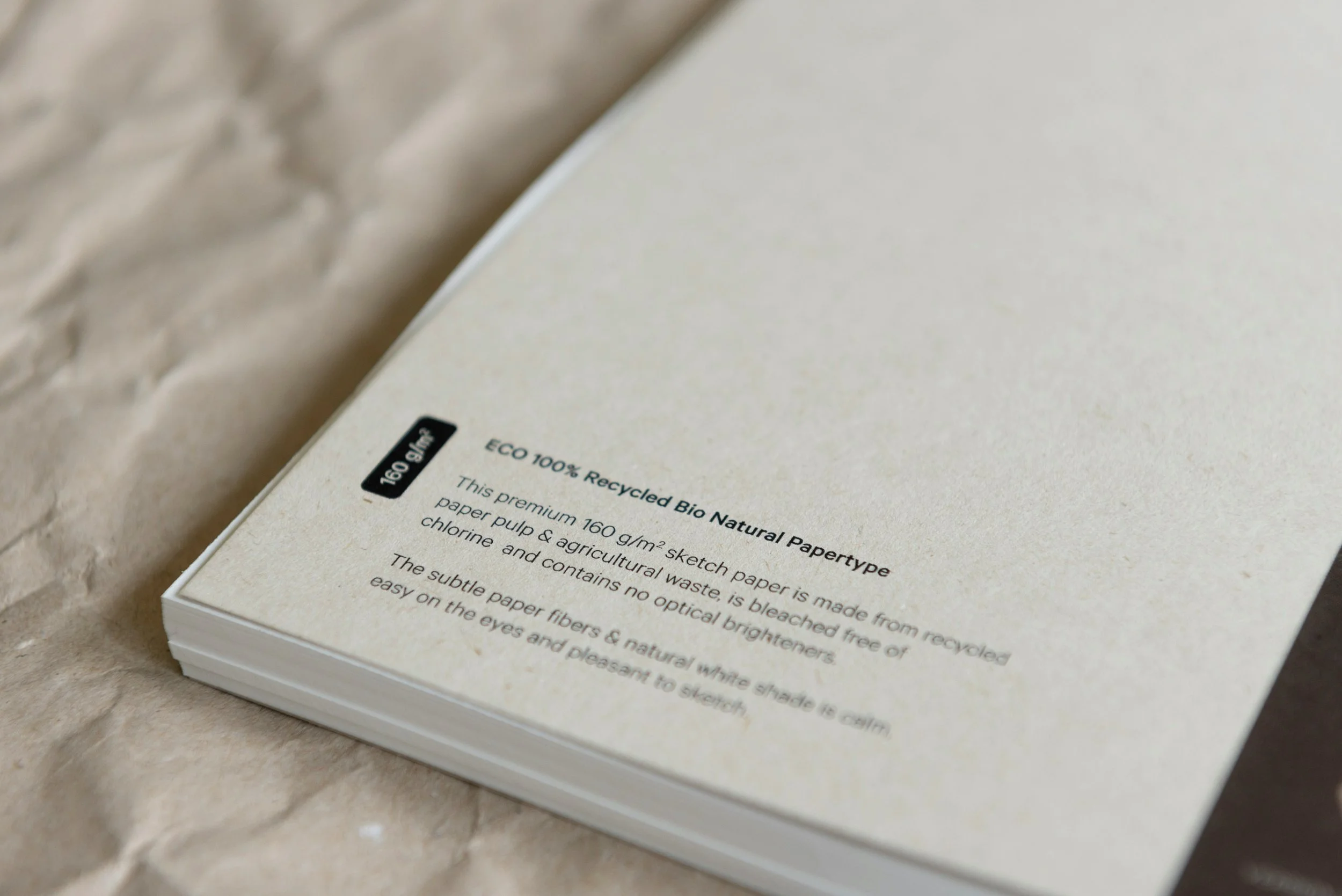

Recycled Stock Performance: Modern recycled and FSC-certified papers are engineered for premium performance, offering high brightness and smooth finishes that ensure sharp text and vivid image reproduction.

Eastern Press ensures that clients no longer have to choose between their bottom line, their brand reputation, and their environmental goals. By embracing smarter technology and superior materials, we are driving the future of commercial print. A future that is fast, high-quality, and responsibly sustainable.